Faced with the increasing pace of aeronautical production between now and 2026, IDEA continues to innovate alongside its aircraft manufacturer customer to optimize its operational logistics and improve the quality and working conditions of its operators capitalizing on the SCALLOG shelves-to-person solution.

IDEA, a major player in the field of tailor-made logistics, continues its ongoing commitment to optimising storage and picking operations for small and medium series parts. Since 2016, the company has successfully integrated an innovative solution that has already reduced storage space by 30% and doubled the picking rate, without disruption to production during this period.

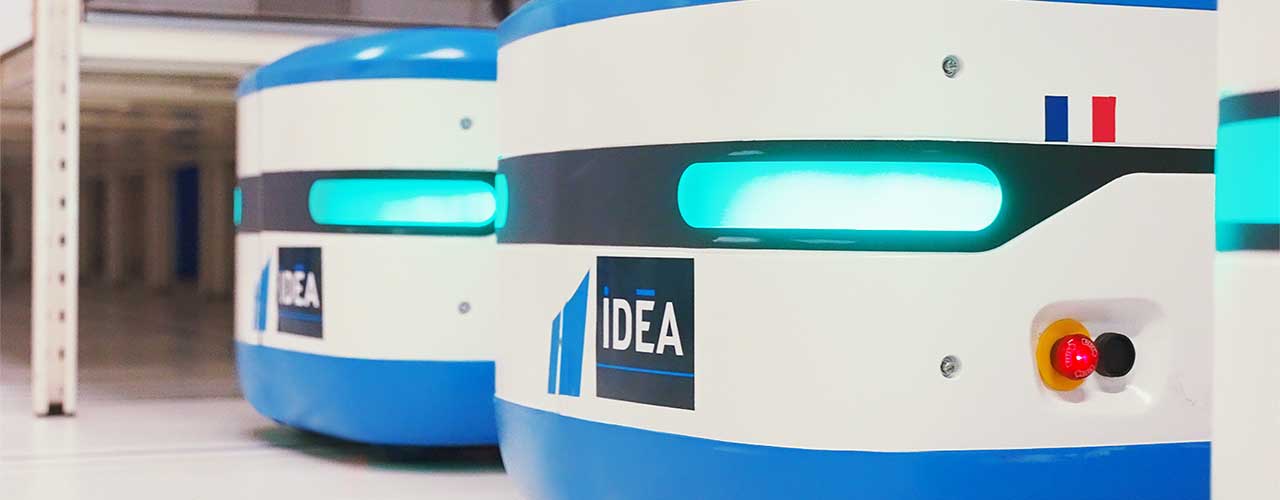

Responding to the evolving needs of the market, a new generation of robots has recently been introduced on the production site. This initiative aims to further improve productivity in the automated warehouse, which now houses a wide range of part SKUs. This installation includes 4 robots, 180 mobile shelves and a workstation.

The tangible benefits of this development are manifold. The solution implemented guarantees an optimization of productivity, an improvement of the working conditions of the operators and a more efficient maintenance, significantly reducing downtime for maintenance.

The tangible benefits of this development are manifold. The solution implemented guarantees an optimization of productivity, an improvement of the working conditions of the operators and a more efficient maintenance, significantly reducing downtime for maintenance.

n the spirit of partnership, discussions are underway to explore new optimization opportunities, particularly in terms of storage space configuration, in order to best adapt the solutions to the changing needs of the market.

Download our IDEA case study to learn more about its innovative logistics.

Would you like to increase the productivity of your order pickers while improving their working conditions? Discover the many advantages of automating your order-picking processes.